1. Utangulizi

This manual provides essential information for the safe and efficient installation, operation, and maintenance of your Pedrollo PQm81-Bs peripheral booster water pump. Please read this manual thoroughly before installation and operation to ensure proper use and to prevent damage or injury.

The Pedrollo PQm81-Bs is designed for pumping clean water that does not contain abrasive particles and liquids that are not chemically aggressive towards the pump's materials. Its compact design and hydraulic characteristics make it suitable for various industrial applications, including cooling systems, air conditioning systems, and ironing systems.

Kielelezo cha 1: Pedrollo PQm81-Bs Peripheral Booster Water Pump. This image shows the blue-colored pump unit with its motor and pump housing, designed for surface installation.

2. Taarifa za Usalama

WARNING: Failure to follow these safety instructions could result in electric shock, fire, serious injury, or death.

- Always disconnect the power supply before performing any installation, maintenance, or repair work on the pump.

- Ensure the electrical installation complies with all local and national electrical codes. The pump requires a 115 Volts (AC) power supply.

- The pump must be installed in a well-ventilated, closed area, protected from adverse weather conditions.

- Do not operate the pump with flammable, explosive, or corrosive liquids. Only use with clean water as specified.

- Weka watoto na wafanyakazi wasioidhinishwa mbali na pampu wakati wa operesheni.

- Ensure proper grounding of the pump to prevent electrical hazards.

- Never run the pump dry. Operating without liquid can cause severe damage to the pump.

3. Kuweka na Kuweka

3.1. Mahitaji ya Mahali

- Install the pump in a well-ventilated area to prevent overheating.

- The installation site must be protected from rain, direct sunlight, and freezing temperatures.

- The pump is designed for above-ground installation. Ensure a stable, level surface for mounting.

3.2. Viunganisho vya mabomba

- Connect the suction and discharge pipes securely. Use appropriate thread sealant to prevent leaks.

- Ensure that the piping system does not place undue stress on the pump connections. Support pipes independently if necessary.

- Install a foot valve with a strainer on the suction line if drawing water from a source below the pump to maintain prime and prevent debris entry.

- For optimal performance, keep suction lift as short as possible. The maximum manometric suction lift is 8 meters.

3.3. Uunganisho wa Umeme

- Connect the pump to a dedicated 115 Volts (AC), 60Hz power supply.

- Ensure the circuit is protected by an appropriately sized circuit breaker or fuse.

- All electrical connections must be made by a qualified electrician and conform to local electrical codes.

- Verify proper grounding of the pump motor.

3.4. Kuweka Bomba

- Before initial startup, the pump casing and suction line must be completely filled with the liquid to be pumped.

- Open the priming plug (if available) or a valve on the discharge side and slowly fill the pump with water until it overflows.

- Close the priming plug/valve. The pump is now primed and ready for operation.

Kielelezo cha 2: Pedrollo PQm81-Bs Pump Dimensions Diagram. This diagram illustrates the physical dimensions and connection points of the pump, including suction (DN1) and discharge (DN2) ports, and overall length (f), height (h), and width (n1) measurements.

4. Maagizo ya Uendeshaji

4.1. Uanzishaji wa Awali

- After priming, ensure all connections are tight and there are no leaks.

- Turn on the power supply to the pump. The pump should start immediately.

- Monitor the pump for unusual noises or vibrations during the first few minutes of operation.

- Check the discharge pressure and flow rate to ensure they are within expected parameters.

4.2. Masharti ya Uendeshaji

- Aina ya Kioevu: Clean water, free from abrasive particles and non-chemically aggressive.

- Joto la Liquid: -10 °C to +90 °C (14 °F to 194 °F).

- Halijoto ya Mazingira: -10 °C to +40 °C (14 °F to 104 °F).

- Manometric Suction Lift: Hadi mita 8 (futi 26).

- Shtaka kubwa ya Kufanya kazi: Paa 10 (psi 145).

- Avoid running the pump dry, as this can cause severe damage to the mechanical seal and other components.

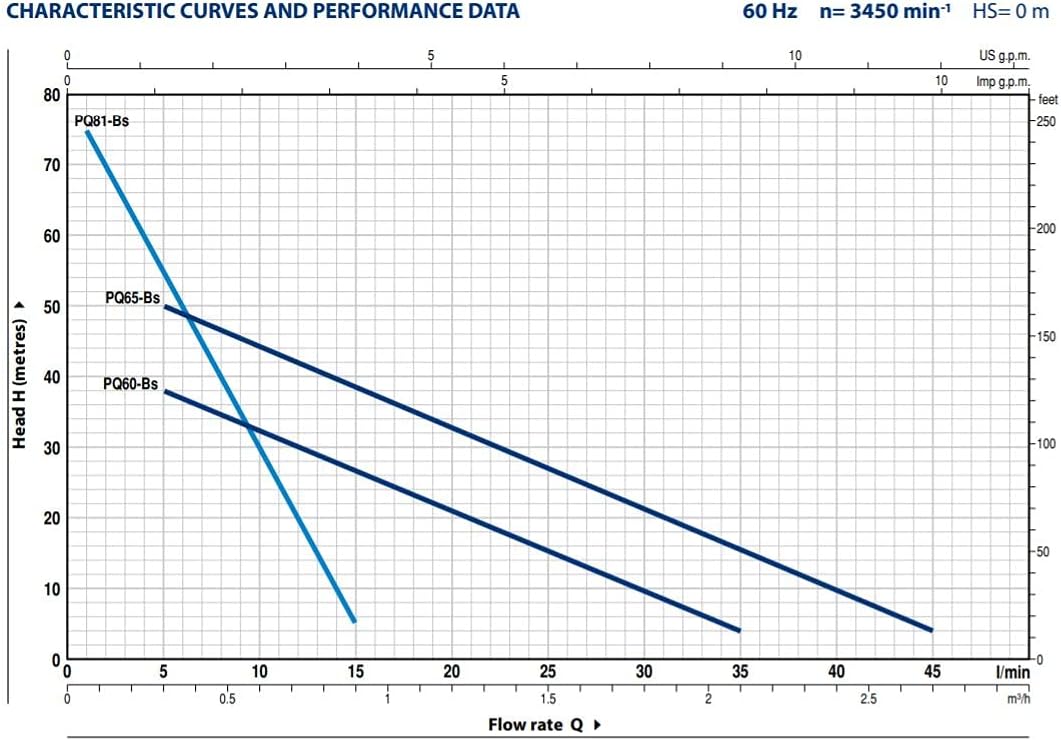

Kielelezo cha 3: Pedrollo PQm81-Bs Performance Curve. This graph displays the relationship between pump head (in meters and feet) and flow rate (in l/min and US g.p.m.) for the PQm81-Bs model at 60 Hz and 3450 min⁻¹ (n=0m), illustrating its operational characteristics.

5. Matengenezo

Regular maintenance ensures the longevity and efficient operation of your Pedrollo pump. Always disconnect power before performing any maintenance.

5.1. Ukaguzi wa Kawaida

- Ukaguzi wa Visual: Periodically check for any signs of leaks, corrosion, or damage to the pump casing, motor, and electrical connections.

- Kelele na Mtetemo: Listen for unusual noises or excessive vibrations, which may indicate a problem.

- Halijoto: Ensure the motor is not overheating. Excessive heat can indicate motor issues or improper ventilation.

5.2. Kusafisha

- Keep the pump exterior clean and free from dust and debris to ensure proper cooling.

- If a foot valve with a strainer is used, periodically check and clean the strainer to prevent clogging and maintain flow.

5.3. Winterization (if applicable)

- If the pump is installed in an area subject to freezing temperatures, drain all water from the pump and piping system to prevent damage from ice expansion.

- Store the pump in a warm, dry place if it is to be out of service for an extended period during cold weather.

6. Utatuzi wa shida

This section provides solutions to common issues. For problems not listed here or if solutions do not resolve the issue, contact qualified service personnel.

| Tatizo | Sababu inayowezekana | Suluhisho |

|---|---|---|

| Pampu haianza | No power supply; Blown fuse/tripped breaker; Motor fault | Check power connection; Reset breaker/replace fuse; Consult a qualified electrician. |

| Pump runs but no water or low flow | Pump not primed; Suction line leak; Clogged strainer/foot valve; Air in system; Impeller damage | Re-prime the pump; Check all suction connections for leaks; Clean strainer; Bleed air from system; Inspect impeller for damage. |

| Kelele nyingi au mtetemo | Cavitation (air in system); Misalignment; Worn bearings; Debris in pump | Ensure pump is fully primed and suction line is sealed; Check mounting for stability; Contact service for bearing inspection; Inspect pump for foreign objects. |

| Uvujaji wa pampu | Loose connections; Damaged seals; Cracked casing | Tighten connections; Replace seals; Contact service for casing repair/replacement. |

7. Vipimo

Technical specifications for the Pedrollo PQm81-Bs Peripheral Booster Water Pump:

| Kipengele | Maelezo |

|---|---|

| Mfano | PQm81-Bs |

| Chapa | Pedrollo |

| Nguvu (HP) | 0.7 HP |

| Voltage | Volti 115 (AC) |

| Mzunguko | 60 Hz |

| Aina ya Kioevu | Maji Safi |

| Kiwango cha joto cha kioevu | -10 °C hadi +90 °C (14 °F hadi 194 °F) |

| Masafa ya Halijoto ya Mazingira | -10 °C hadi +40 °C (14 °F hadi 104 °F) |

| Max. Manometric Suction Lift | Mita 8 (futi 26) |

| Max. Shinikizo la Kazi | Pau 10 (psi 145) |

| Nyenzo | Stainless Steel (housing, specific components) |

| Mtindo wa Ufungaji | Juu ya Ardhi |

| Vipimo vya Bidhaa (L x W x H) | Takriban inchi 12 x 8 x 8 |

| Uzito wa Kipengee | Pauni 16 |

| UPC | 722777873488 |

8. Udhamini na Msaada

Warranty information for your Pedrollo PQm81-Bs pump is typically provided with the product at the time of purchase. Please refer to the documentation included in the product packaging for specific warranty terms and conditions.

For technical support, spare parts, or warranty claims, please contact your authorized Pedrollo dealer or the manufacturer directly. Keep your purchase receipt and product serial number available when seeking support.