1. Utangulizi

Thank you for choosing the ENGINEER NS-04 Precision Mini Nippers. These professional-grade side cutting pliers are designed for precise cutting tasks, particularly in electronics, PCB work, and hobby applications. Featuring hardened carbon steel jaws and ESD-safe comfort grips, the NS-04 offers reliable performance and user comfort. This manual provides essential information for safe operation, maintenance, and optimal use of your tool.

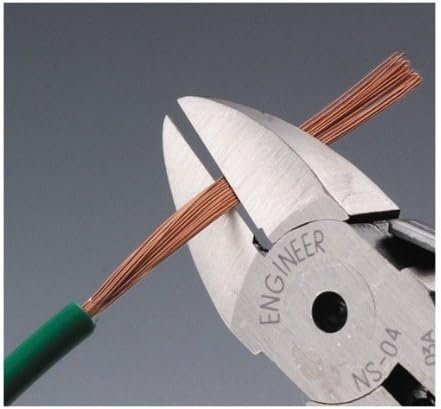

Image 1: The ENGINEER NS-04 Precision Mini Nippers, showcasing their compact design and ESD-safe grips.

2. Taarifa za Usalama

Always observe the following safety precautions when using the ENGINEER NS-04 nippers to prevent injury and tool damage:

- Vaa Kinga ya Macho: Always wear safety glasses or goggles to protect your eyes from flying debris during cutting operations.

- Matumizi Yanayokusudiwa: These nippers are designed for cutting soft materials such as copper wire, electronic component leads, and plastic. Do not use them for cutting hard materials like steel wire, piano wire, or screws, as this can damage the cutting edges.

- Mtego Sahihi: Maintain a firm and secure grip on the handles during use.

- Weka Vidole Wazi: Ensure fingers and other body parts are clear of the cutting jaws.

- Hifadhi: Store the nippers in a dry, safe place, out of reach of children.

- Ukaguzi: Before each use, inspect the nippers for any signs of damage, such as chipped jaws or loose handles. Do not use damaged tools.

3. Bidhaa za Bidhaa

The ENGINEER NS-04 nippers incorporate several design elements for precision and durability:

- Ukubwa Kompakt: Ideal for precise work in confined spaces, such as PCB assembly, electronics repair, and intricate craft projects.

- Flush Cutting Edges: Specially designed for clean, flush cuts on electronic components, copper wire, and soft lead wires, minimizing protrusions.

- Hardened Carbon Steel Jaws: Constructed from heat-treated carbon steel for exceptional cutting performance and extended durability.

- Angle Opening Adjuster: A mechanism that allows adjustment of the maximum jaw opening when the grips are released. This feature enhances productivity and reduces hand fatigue during repetitive cutting tasks.

- ESD Safe Comfort Grips: Handles made from oil-resistant thermoplastic elastomer, providing a comfortable and secure grip while offering electrostatic discharge (ESD) protection.

Picha 2: Karibu view of the NS-04 nippers highlighting the jaw opening adjustment setting and the ergonomic comfort grips.

4. Kuweka na Ukaguzi wa Awali

The ENGINEER NS-04 nippers are ready for use directly out of the packaging. No assembly is required.

- Ondoa: Carefully remove the nippers from their packaging.

- Ukaguzi wa Visual: Examine the nippers for any visible damage that may have occurred during shipping. Check the cutting edges for chips or misalignment.

- Ukaguzi wa Utendakazi: Open and close the handles a few times to ensure smooth operation and proper spring action. Verify that the jaw opening adjuster functions correctly.

5. Maagizo ya Uendeshaji

Follow these steps for effective and safe use of your nippers:

- Tambua Nyenzo: Ensure the material to be cut is within the nippers' capacity (soft copper wire, plastic, component leads). Avoid hard materials.

- Nafasi: Place the material as deep as possible into the jaws for optimal leverage and a clean cut. For flush cuts, position the flat side of the nipper jaws against the surface from which you are cutting.

- Hatua ya kukata: Apply steady, firm pressure to the handles until the cut is complete. Avoid twisting or prying with the nippers.

- Jaw Opening Adjustment: To adjust the maximum opening of the jaws, locate the small screw mechanism between the handles near the pivot point (refer to Image 2). Loosen the screw slightly, set the desired maximum opening, and then tighten the screw to secure the setting. This is useful for repetitive tasks to reduce hand movement.

Image 3: The NS-04 nippers demonstrating a clean cut on a copper wire.

6. Matengenezo na Matunzo

Proper maintenance ensures the longevity and performance of your nippers:

- Kusafisha: After each use, wipe the nippers clean with a dry, soft cloth to remove any debris or residue.

- Upakaji mafuta: Periodically apply a small drop of light machine oil to the pivot point to maintain smooth operation. Wipe off any excess oil.

- Hifadhi: Store the nippers in a protective pouch or tool tray to prevent damage to the cutting edges. Keep them in a dry environment to prevent rust.

- Epuka Kuanguka: Dropping the nippers, especially on hard surfaces, can damage the precision-ground cutting edges.

7. Utatuzi wa shida

If you encounter issues with your nippers, consider the following:

- Operesheni Ngumu: If the nippers feel stiff, apply a small amount of light machine oil to the pivot point and work the handles to distribute the lubricant.

- Utendaji mbaya wa kukata: Ensure you are cutting appropriate materials. If the cutting edges appear dull or damaged, the nippers may require professional sharpening or replacement. Do not attempt to sharpen the precision edges yourself unless you have specialized tools and expertise.

- Jaws Not Closing Completely: Check for any debris lodged between the jaws or at the pivot point. Clean thoroughly. If the issue persists, the tool may be damaged.

8. Vipimo

| Kipengele | Vipimo |

|---|---|

| Nambari ya Mfano | NS-04 |

| Urefu wa Jumla | 120 mm (inchi 4.72) |

| Nyenzo | Hardened Carbon Steel (Jaws), Alloy Steel (Handle) |

| Kushughulikia Nyenzo | Thermoplastic Elastomer (ESD Safe) |

| Uzito wa Kipengee | Gramu 83 (wakia 2.93) |

| Vipimo vya Bidhaa | 1.97"Upana x 4.72"Upana (takriban) |

| Kukata Upana | Sentimita 0.26 |

| Aina ya Mtego | Ergonomic |

| Kuzingatia | RoHS |

Image 4: Technical diagram illustrating the dimensions of the ENGINEER NS-04 nippers.

9. Udhamini na Msaada

ENGINEER products are manufactured to high standards and are designed for durability. For specific warranty information, please refer to the documentation included with your purchase or visit the official ENGINEER website. If you require technical assistance or have questions regarding your NS-04 nippers, please contact ENGINEER customer support through their official channels.

For further information and product details, you may visit the ENGINEER Store on Amazon.